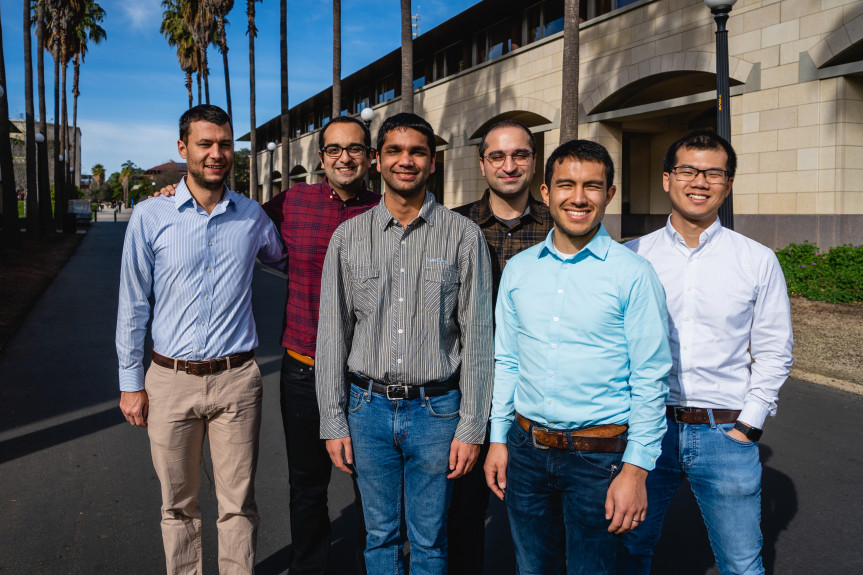

Stanford Professor Stefano Ermon, from left, Stanford Ph.D. alumnus Peter Attia, Stanford Ph.D. student Aditya Grover, Toyota Research Institute scientist Muratahan Aykol, TRI scientist Patrick Herring, Stanford professor William Chueh. (Photo by Farrin Abbott)

How many scientists does it take to design a better battery? According to a new study, artificial intelligence might do it better and faster than human scientists ever could.

Researchers at Stanford University employed artificial intelligence to work out a method for rapidly charging a battery while minimizing the impacts on the battery’s lifespan. The technique, a form of AI called machine learning optimization, revealed an ideal charging method in a fraction of the time it would have taken using traditional experiments. It’s a method that the scientists say can shorten the time it takes to design better batteries in the future.

“The goal was to get better batteries faster. Our paper provides one solution, which is to use artificial intelligence to speed up the process,” said William Chueh, a materials scientist at Stanford who co-led the team.

Improving batteries is a major step in California’s goal of reaching carbon-free electricity by 2045. Batteries are necessary for storing electricity generated by wind and solar. And battery-powered electric cars are becoming more common around the Bay Area and beyond, reducing greenhouse gas emissions.

“The reason this is exciting is because battery research and development is a really long process … batteries last a really long time,” Chueh said. “You don’t get the instant reward of knowing if something worked or not.”

The team, which included scientists from the Toyota Research Institute, wanted to apply a machine learning approach to a specific problem: charging an electric car battery to 80% of its capacity in only 10 minutes, while minimizing stress on the battery that would shorten its life.

“People don’t want to take a road trip and then have to wait 40 minutes to recharge,” said Peter Attia, the lead author of the study, which was completed when he was a graduate student at Stanford. Attia said the fear of running out of a charge is a common deterrent to electric car ownership.

Normally, testing a new battery design requires observing how the battery behaves over repeated charging cycles — a process that can take years before the battery fails. Instead of this lengthy approach, the researchers fed “training data” from past experiments into a computer, teaching it to accurately predict how long the batteries would last after only 100 charging cycles. That shortened the process of testing a battery with each charging method from 40 days to four.

Then, the computers detected patterns in the results of each experiment, and whittled down the options for the next round of tests, speeding up the process even more.

“Humans don’t usually work that way. We have intuitions,” Chueh said. “We think a certain thing works better based on our understanding of the process.”

He said the AI tested 224 different charging methods, and produced a solution in just 16 days. That process would have normally required over a year and a half to accomplish.

“It’s a pretty big multiplier in terms of time-saving,” Chueh said. “Not to mention, the answer you arrive at may be better than the one that you would get in the ordinary approach.”

While this particular example used artificial intelligence to identify the best way to charge a battery, the researchers said AI could improve all aspects of battery design, from the way they’re manufactured to their internal chemistry.

“I’m pretty excited about the future of AI development,” Attia said. “AI gets a lot of flack for being used for (advertising). But I think there’s a lot of excitement now for getting AI to accelerate science.”

Attia notes that machine learning is also being used in the field of genetics, to create better cancer treatments, and to speed up pharmaceutical development.

But using complicated machine learning programs is a bit of a black box, according to Matthieu Dubarry, a battery specialist at the Hawaii Natural Energy Institute.

“You could get a result without understanding how you got there,” he said. “As a scientist, that bothers me a little.”

Dubarry cautions that speeding up the design process using machine learning depends on the strength of the training data involved, which has to reflect the particular qualities of a type of battery and how it’s being used.

“I don’t think you can really extrapolate their result to another application, even for that same battery,” he said. “Battery degradation is extremely dependent on the way (the battery) is used.”

To fully understand how a different charging method might change between different batteries, and different applications, Dubarry said you need “more diverse training data.” And that training data is produced the old-fashioned way: with lots of time-intensive testing.

But Dubarry also agrees that there are some big advantages to using AI.

“The work they did is a really great starting point, they did a wonderful job,” he said. “No doubt their approach will lead to some major discoveries.”

Chueh said he’s driven to increase the development of technologies, like batteries, that can help mitigate climate change. Using AI is a way to achieve that goal.

“Many people are working on better batteries, so we have less expensive electric vehicles, and solar and wind electricity that’s available 24/7” he said. “I’m constantly asking myself … can we do it faster? Because time is limited.”

Machines drive better battery designs: Study - by Jerimiah Oetting - The Mercury News - February 29th, 2020